YEARS

Professional experience in the production of auto parts

RECOMMENDED

POPULAR PRODUCTS

WHO WE ARE?

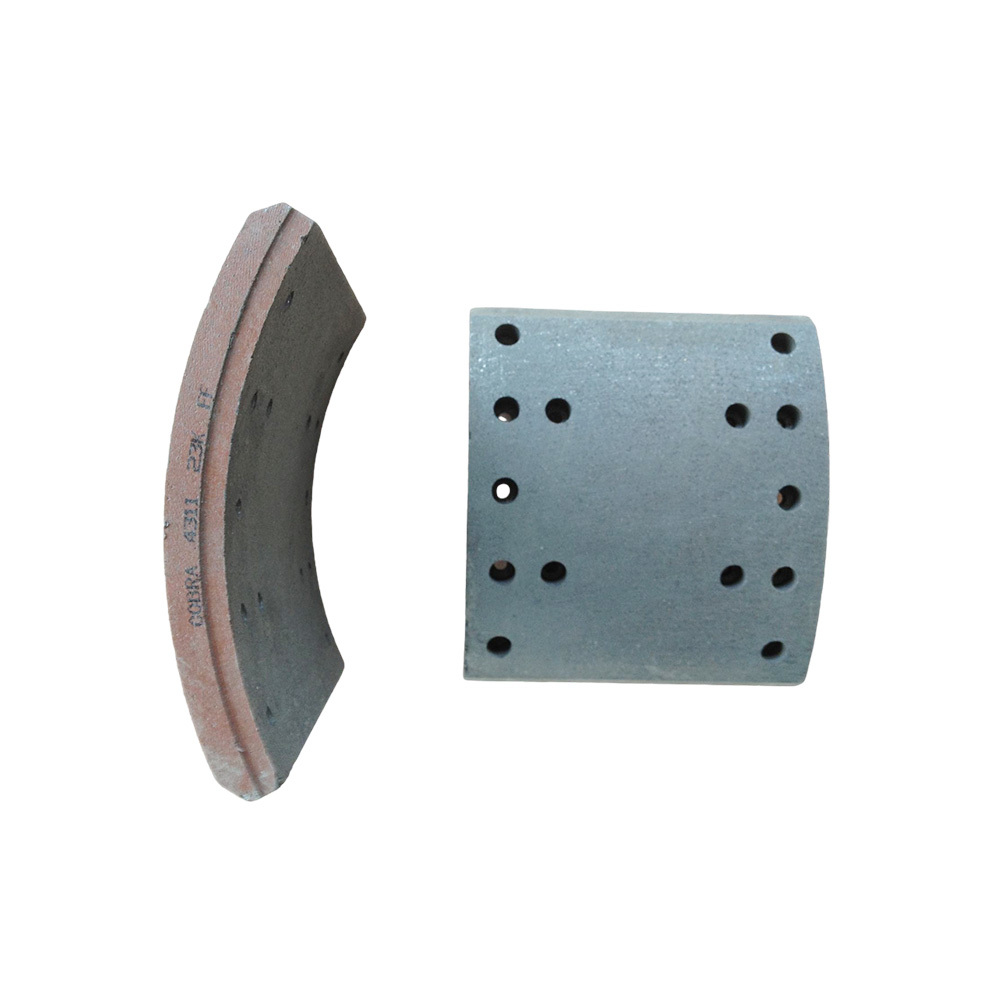

Tim Brake Parts

Tim Brake Company specializes in the production of brake pads, brake linings, camshafts and repair kit assemblies. The products have passed the relevant standards in the domestic automotive industry and are characterized by high strength, heat resistance, wear resistance, lack of pollution, noiselessness and stable operation.

Currently, this series of products is sold to countries and regions such as North America, Europe, the Middle East, Australia, as well as domestic manufacturers and after-sales markets.

NEWS INFORMATION

EVENTS

Apr 06,2025

Heavy drag brake cooling system

Introduction to relative advantages and disadvantages 1: Drip brakes are prone to causing road icing in low temperature conditions, which can easily lead to traffic accidents. 2: When the drip brake is applied at low temperatures, the spray head may freeze, causing the tire temperature to be too high and leading to fire accidents. 3: The heavy drag brake cooler uses cooling oil to prevent liquid from flowing out and causing road icing.

Apr 06,2025

The country has not mandated the lifespan of brake pads in kilometers, as the usage of vehicles is very complex. However, there are still standardized quality standards for the durability of automotive brake pads. For example, regarding disc brake calipers and brake pads, the standard stipulates that their durability should be able to brake 500000 times at room temperature, 70000 times at high temperature (120 ℃), and over 45000 times at low temperature (-40 ℃) when subjected to a hydraulic pressure of 7Mpa. In daily use, ordinary brake pads should be inspected after 25000 kilometers, and the replacement time should be determined based on the specific wear condition.

Apr 06,2025

The future development of the brake pad industry will present the following trends

From the perspective of macro development direction, focus on technological innovation and enhance core competitiveness. Market advantage relies on technological advantage to support it, and the soul of technological progress lies in innovation.

Precision Machining and Special Processes

In the process of precision machining, due to the high precision and quality requirements of mechanical parts, it is necessary to match the parts according to customer requirements, production batch and precision to achieve good results. Therefore, in terms of parts matching, we can carry out product design according to the customer's product demand and production batch, and then carry out precision machining.

27 Mar,2025